We produce hyperpressed bricks

based on the ECOS technology

(Economical Composite Optimized System).

Durable. Eco-friendly. Efficient.

🧱 Who We Are

We are 4Bricks, a team of engineers, architects, and entrepreneurs united with the goal of transforming the construction materials market in the Czech Republic and the EU.

♻️ ECOS

At the core of our work is the ECOS (Economical Composite Optimized System) — universal, environmentally and economically optimized construction mixes developed by our team. We also create a new generation of hyperpressed bricks, combining durability, precision, and aesthetics.

The ECOS technology will serve as the foundation for the 4Bricks product line and will make it possible to create affordable, durable, and environmentally safe building materials that meet the trends of sustainable construction.

🌍 Mission

We create innovative construction solutions with a focus on eco-friendliness, precision, and adaptation to EU standards.

🔬 Technology

Our product is manufactured using a hyperpressing method without firing, utilizing recycled raw materials and ensuring precise geometry of ±0.5 mm.

📍 Geography

We are based in the Czech Republic and plan to scale across Europe — starting with Germany, Austria, and Slovakia.

🧱 Our Product

We produce a new generation of hyperpressed bricks — without firing, with high precision, excellent aesthetics, and a minimal carbon footprint.

⚙️ Technology

Semi-dry hyperpressing method under 10–15 tons of pressure. No firing, with up to 90% recycled raw materials used.

🏗️ Strength

Bricks withstand loads up to M300, frost resistance F150–F300. Suitable for facades, walls, partitions, and landscaping.

🌿 Sustainability

CO₂ emissions reduced by 70% compared to firing. Certified under EN 771-3, Blue Angel certification expected.

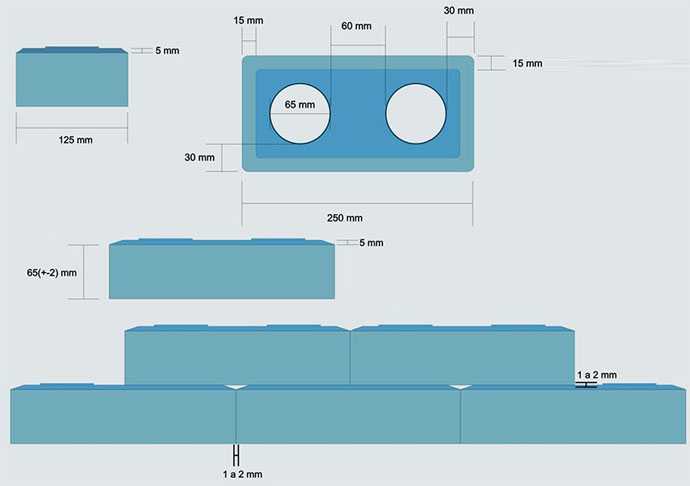

Sample 4Bricks product

💡 Our Advantages

4Bricks is not just a brick. It is a new approach to construction, where technology, sustainability, and cost efficiency come together.

♻️ No Firing

Energy savings and carbon footprint reduction of up to 70%. Use of recycled materials.

📐 Perfect Geometry

Deviation no more than ±0.5 mm. This speeds up masonry and reduces mortar consumption by up to 30%.

🏗️ Strength

Frost resistance F150–F300, strength up to M300. An excellent choice for facades and load-bearing walls.

🎯 Project Adaptability

Possibility to integrate channels for reinforcement and utilities. Suitable for BIM and tender requirements.

🎨 Aesthetics

Smooth texture, coloring options available. The brick can be used both indoors and on facades.

🚛 European Logistics

Delivery across the Czech Republic and the EU, fast packaging, pallet supply, and project-based calculations.

❓ Frequently Asked Questions

Answers to the most common questions from clients and partners.

🧱 How is hyperpressed brick different from regular brick?

Our bricks are produced without firing, which helps preserve natural resources, reduce CO₂ emissions, and at the same time ensures high strength and aesthetics. It is an eco-friendly and precise material of the new generation.

📦 How are delivery and packaging carried out?

Supply is carried out on pallets (336–420 pcs), with products wrapped in stretch film and branded labeling. Delivery is available throughout the Czech Republic and EU countries.

📐 Is it possible to order bricks in custom sizes?

Yes, we can design a mold for the required shape and size depending on the project. Options with recesses for reinforcement and utilities are also possible.

📄 What documents do you provide?

Each batch is accompanied by a technical datasheet, certificates of conformity (EN 771-3), and, if necessary, adaptation to tender documentation.

🏗️ Is your product suitable for government projects?

Yes. Our bricks comply with EU standards and eco-standards (Blue Angel certification in progress), making them an ideal choice for the B2G segment.

📦 What We Offer

We create not just bricks, but a complete ecosystem of products and solutions for fast, reliable, and eco-friendly construction within the EU.

🧱 Hyperpressed Bricks

Basic and facing bricks. Gray and colored. Hollow, solid, with recesses for reinforcement.

📐 Custom Shapes

Possibility of made-to-order production — corner elements, decorative modules, non-standard formats.

📋 Certification and Calculations

Supporting documentation, EN 771-3, assistance with tenders, project specifications, and BIM.

🔧 Related Solutions

Concrete blocks, landscaping elements, partitions, decorative panels for facades and interiors.

🧱 Overview of Features

What is a Lego Brick?

A brief overview of the material, technology, and its unique features

Lego brick is a modern building block produced by pressing without firing. It is based on cement mixtures and natural mineral components. This approach makes production eco-friendly, and the brick itself strong and geometrically precise.

⚙️ Production Technology

Manufactured from a cement-lime or cement-sand mixture with the addition of dolomite, travertine, and other natural components. Production without firing reduces costs and preserves natural resources. High-pressure pressing and drying allow for a high-strength block without the use of high temperatures.

🔗 Design and Features

The Lego brick is equipped with a "tongue-and-groove" system that ensures precise alignment and even masonry. Two through-holes help reduce weight, allow alignment, and provide space for utility installation. The geometry of the brick is accurate to the millimeter, simplifying the laying process and making it accessible even to non-professionals.

⚙️ Constructor Principle

The blocks connect like building set pieces — quickly, precisely, and without mistakes. The geometry ensures automatic alignment without special skills.

🧩 Material Potential

Thanks to its precise shape and variety of colors, Lego brick is used both in load-bearing construction and decorative architecture.

🧠 Constructor Principle

The blocks connect like building set pieces — quickly, precisely, and without mistakes. The geometry ensures automatic alignment without special skills.

🪨 Mineral Base

The composition includes crushed rocks: limestone, dolomite, screenings — which ensures strength and durability.

🎨 Variety and Aesthetics

A wide range of shapes, colors, and textures allows the brick to be used for facades, interiors, and fences — without additional finishing.

🧱 Where is Lego Brick Used?

Thanks to its universal shape and high strength, Lego brick is suitable both for private housing construction and for decorative architectural solutions.

Private houses, gazebos, summer kitchens, and barbecue areas — Lego brick is widely used in the construction of small structures where easy laying and aesthetics without additional finishing are important.

It is ideal for partitions and load-bearing walls, columns and supports, as well as permanent formwork in monolithic construction. It is also used for building fences and decorative enclosures, which makes it popular in landscape architecture and among private builders.

Thanks to the ability to choose color and texture, the material is also used in small architectural forms (SAF), such as garden elements and outdoor decor.

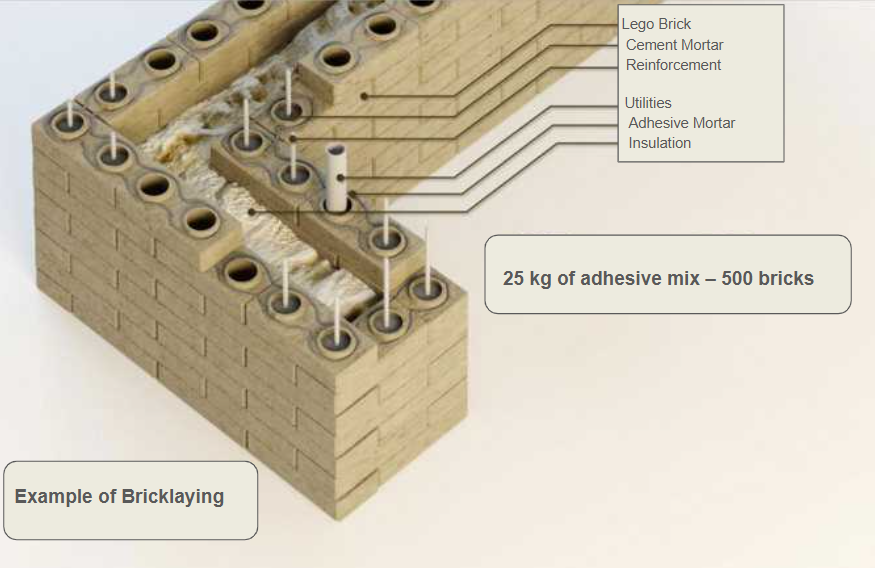

🏗️ How Are Lego Brick Houses Built?

Modern technology makes it possible to build energy-efficient houses with high strength. Masonry is laid in two rows with insulation placed between them. Vertical cavities are reinforced with rebar and, if necessary, filled with concrete.

- Two parallel rows of bricks;

- Insulation between them (polystyrene foam, expanded clay, polyurethane);

- Vertical reinforcement through internal cavities;

- Finished facade with no need for cladding.

This design ensures resistance to temperature fluctuations, increased humidity, and retains heat throughout the year.

🏡 Advantages of Brick Houses

Why brick houses remain the No. 1 choice for decades ahead

⏳ Durability

A brick house can last 100–150 years with proper construction technology. It withstands freeze-thaw cycles while maintaining its strength for decades.

🔥 Fire Safety

Even in the event of a fire, brick walls retain their shape and load-bearing capacity, providing additional protection for residents.

🪳 Protection from Pests and Mold

Brick is resistant to insects and fungi, making it more hygienic and durable compared to wood.

🏗️ Strength

Thanks to its high load-bearing capacity, brick is widely used in the construction of multi-story buildings and structures with increased loads.

🌦️ Climate Resistance

Brick walls are resistant to precipitation, wind, and temperature fluctuations. This makes them especially reliable in regions with harsh winters and humid climates.

💨 Natural Ventilation

Brick "breathes," providing a healthy indoor climate without the airtightness typical of panel houses.

🌡️ Thermal and Sound Insulation

Massive brick walls retain warmth in winter and coolness in summer for a long time, while effectively reducing street noise.

🎨 Aesthetics and Variety

A wide choice of colors, textures, and shapes allows for original architectural solutions — from classic to modern designs.

🧱 Versatility in Finishing

Brick is compatible with most finishing materials: plaster, tiles, wood, decorative panels.

🌱 Eco-friendliness

Brick is made from natural components and is safe for both human health and the environment.

🧱 History and Evolution of Lego Brick

📚 Origin Story

The history of Lego brick begins in Denmark, where carpenter Ole Kirk Christiansen created the first toy constructor in 1932. In 1949, a construction brick based on the same principle appeared. By the 1950s, the technology had already spread to the construction industry.

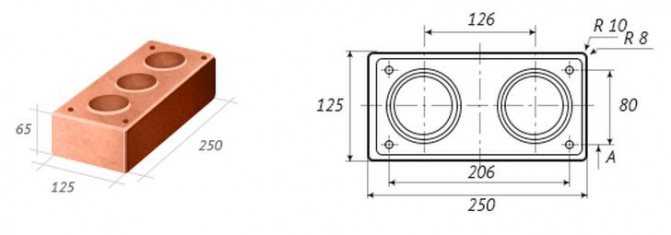

🧱 Modern Lego Brick

This is a durable block in the form of a parallelepiped, produced by pressing. The top part has round protrusions, and the bottom has recesses for a tight fit. Some models include side centering elements for perfect alignment.

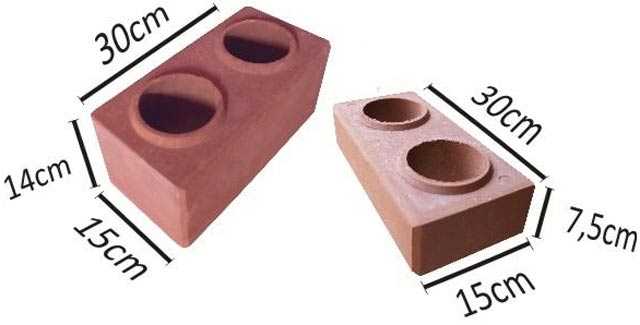

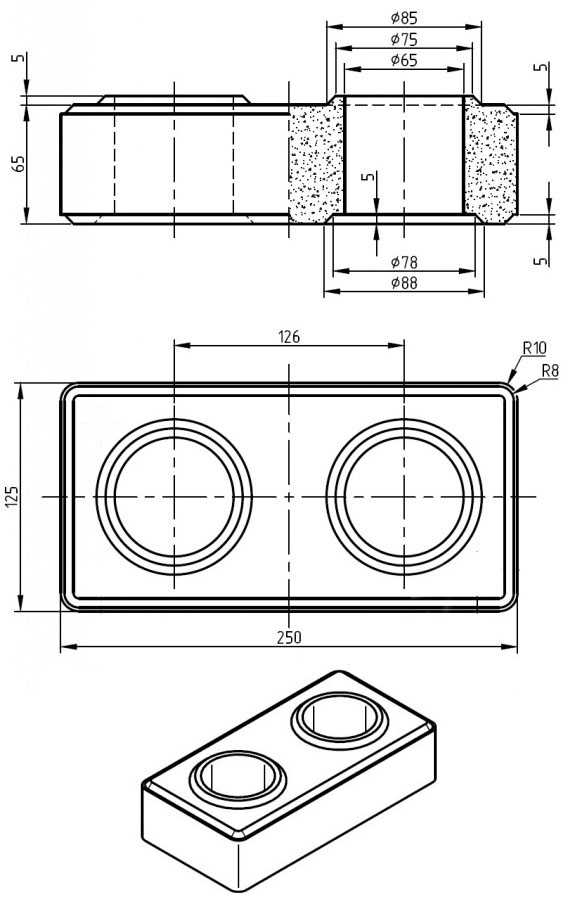

📐 Design and Characteristics of Lego Brick

Dimensions, shape, and key parameters of strength and thermal efficiency

Shape and Jointing: Lego brick is equipped with two rounded studs that provide precise fitting using the "tongue-and-groove" principle. This allows walls to be assembled without complex adjustments and minimizes the risk of misalignment.

Purpose: Suitable for constructing both partitions and load-bearing walls. Thanks to its strength and geometry, the brick can be used in projects of any complexity.

Dimensions and Weight: Standard dimensions are 250 × 125 × 45–80 mm, with each unit weighing 3.5–4 kg. Each block has two holes with a diameter of 65 mm, improving bonding and making it easier to install utilities.

Frost Resistance: The material withstands more than 200 freeze-thaw cycles without structural damage. This makes it particularly reliable in cold climate zones.

Density: Approximately 1550 kg/m³ — the optimal balance between strength, load resistance, and structural weight.

Thermal Conductivity: Ranges from 0.4–0.45 W/(m·K), which helps effectively retain heat indoors and reduces energy costs for heating.

📏 Dimensions and Structural Features

Geometry, precision, and standards — everything you need to know

Standard Dimensions: A classic Lego brick has dimensions of 250×125×65 mm. It is equipped with two round holes of 65 mm in diameter, positioned 60 mm apart. The top surface features studs 5 mm high, ensuring precise alignment during masonry.

Joint Precision: For stable and aesthetic masonry, it is important to maintain accurate geometry: the distance from the edge to the center of the hole is 30 mm, and the positioning angles of the studs and grooves are exactly 15 mm. Even minimal deviations can affect wall alignment.

🧱 Lego Brick vs Classic: An Objective Comparison

How the innovative block differs from traditional brick

| Characteristic | Classic Brick | Lego Brick |

|---|---|---|

| Density | 1600–1900 kg/m³ | 1550 kg/m³ |

| Strength Grade | M150 | M150 |

| Frost Resistance | 35–40 cycles | 35–40 cycles |

| Brick Weight | 3.3–4 kg | 3–3.5 kg |

| Water Absorption | 6–14% | 5–6% |

| Thermal Conductivity | 0.5–0.8 W/(m·K) | 0.4–0.56 W/(m·K) |

Despite similar density indicators, Lego brick is lighter and easier in terms of logistics. It is transported faster, lifted more easily to upper floors, and reduces the load on the foundation. Lower water absorption makes it more resistant to moisture and temperature fluctuations — ideal for unstable climates.

An additional advantage is the ability to set up production directly at the construction site, which is especially relevant in peak season when factory deliveries are delayed. On-site production means savings and flexibility without compromising quality.

🏠 Operational and Technological Features

🏠 Operational Advantages

- Reduced thermal conductivity

- High frost resistance

- Minimal water absorption

- Increased wear resistance

The unique design with holes and a “stud–groove” system increases the building’s stability, including resistance to seismic loads. Using frost-resistant tile adhesive makes the masonry process easier and cheaper. The strength of such masonry is about 70% higher than that of silicate brick, while the load on the foundation is significantly lower.

⚙️ Technological Features

Frost-resistant tile adhesive is used in masonry, which can be applied with a gun, roller, or even a homemade dispenser. The holes can be used for laying electrical wiring, inserting reinforcement, or filling cavities with concrete to strengthen the structure. In terms of strength, Lego brick can surpass ceramic brick by up to 50%, while still being lighter.

💸 Lego Brick Masonry — Savings and a Start Without Experience

Easy installation and real financial benefits even for beginners

No experience — no problem. Thanks to the “stud–groove” connection system and precise geometry, Lego brick can be laid independently. It’s almost like assembling a building set: accuracy, a level, and a bit of practice are all you need.

Reduced costs. In the Czech Republic, masonry of 1 m³ costs around 4,000 CZK (~160 EUR), while in Germany it ranges from 250 to 400 EUR. By doing 40 m³ yourself, you save:

- 🇨🇿 up to 160,000 CZK (≈6,400 EUR)

- 🇩🇪 up to 16,000 EUR or more

Start small. If you are unsure, begin by hiring a specialist to lay the first row. This is the foundation of the entire masonry. After that, you can continue on your own using video guides and diagrams.

Self-learning made easy. The internet is full of detailed video instructions explaining every stage of masonry. This makes Lego brick an excellent solution for those who want to build a house themselves or start a new business.

Lego brick is not just a convenient material. It’s an opportunity to save money, learn something new, and build a house with your own hands at minimal cost.